|

新聞詳情

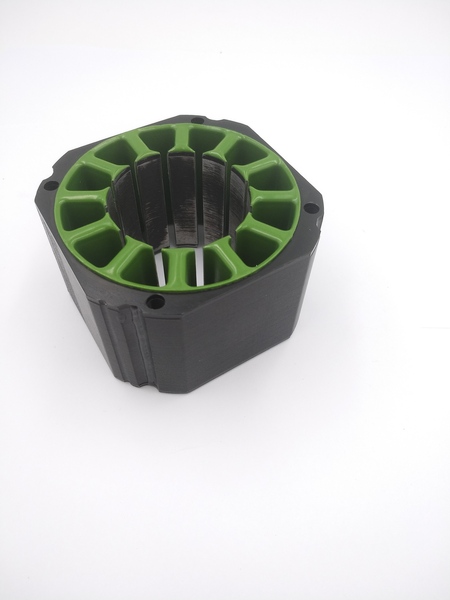

How to perform anti-rust treatment on the stator core發(fā)表時間:2018-05-04 10:11 Generally speaking, the silicon steel sheets of the stator itself have an insulating coating. As long as it is not in a special environment, the inter - layer is not easily corroded. However, on the punching and shearing surfaces of the stator and rotor, since Fe directly reacts with the air, if anti - rust treatment is not carried out immediately after punching, the iron core generally will rust to varying degrees within 1 - 2 weeks. But even if anti - rust treatment is adopted, if the motor's working environment is relatively humid or there is water mist, such as the motor of a plant protection machine, then special anti - rust treatment needs to be carried out for the product; we also call it electrophoretic spraying. Color: Black Thickness: 0.013 - 0.025mm, the maximum thickness can reach 0.1mm Anti - rust ability: It can pass the 24 - hour salt spray test.

|